Are you in need of finding flaws in materials without breaking them apart? One cool way to do this is by using PAUT Phased Array Ultrasonic Testing. This method sends sound waves into materials to spot any sneaky cracks or faults.

Our article will guide you through how it works, making the tricky stuff easy to get. Stick around, and let’s uncover the magic of PAUT!

Overview of Phased Array Ultrasonic Testing (PAUT)

What is PAUT?

PAUT stands for Phased Array Ultrasonic Testing. It’s a smart kind of test to find flaws in materials without breaking them. This method uses special sound waves that go deep into objects like pipes, boats, and even aeroplanes to check for cracks or other problems.

The cool part? PAUT can look at different angles and parts all at once because it controls the sound wave direction.

Now, imagine using a superpower to see inside things without opening them—that’s what PAUT does. It shoots these sound waves in patterns and collects echoes bouncing back from inside the material.

By studying these echoes, experts can tell if something is wrong inside the object being tested. So next up, let’s chat about how this amazing tech works its magic.

How does it work?

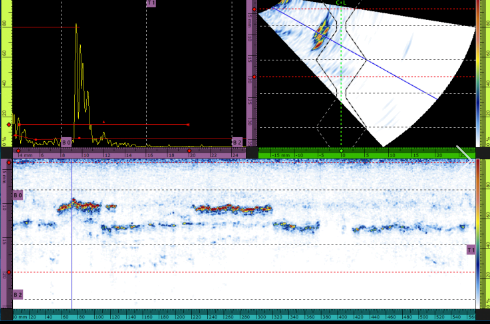

Phased Array Ultrasonic Testing (PAUT) sends sound waves into materials to find flaws. This method uses many small ultrasonic sensors in a phased array. These sensors send out sound waves at different times and angles.

The way the waves bounce back tells us if there are any defects in the material.

This technique allows for precise control over the beam direction and angle, making it easier to inspect complex shapes and sizes. It’s like having X-ray vision that can see inside metal parts or composite materials without cutting them open! The data from these sound waves is then turned into images on a computer, showing exactly where problems might be hiding.

This makes PAUT a super tool for checking things like pipes, bolts, and even aeroplanes for safety.

Components of a PAUT system

So, we just talked about how PAUT works, right? Cool stuff! Now, let’s get into the nuts and bolts of a PAUT system. Imagine it like a superhero gadget belt – each part has its own special role.

- Ultrasonic Transducer – This bit is the hero of our story. It sends out sound waves and listens for echoes. These echoes bounce back from flaws or cracks in the material being checked. Think of it as shouting in a canyon and listening for echoes.

- Phased Array Controller – Picture this as the brain behind the operation. It tells the transducer exactly when to send out sound waves. It’s like conducting an orchestra, making sure every instrument plays at the right moment.

- Software – Every hero needs a sidekick, right? Here’s where software comes in. It takes all that echo info from the transducer and turns it into images or data we can actually understand. Like translating alien language into English.

- Scanning Mechanism – This part moves the transducer over whatever’s being inspected so it can check out different areas without missing a spot. Imagine moving a metal detector over the ground looking for treasure.

- Display Unit – Last but certainly not least, this is where all that data shows up so inspectors can see what’s going on inside the material. It’s like watching a film where the sound waves are the stars.

Each component plays its part in spotting flaws deep within materials, ensuring everything from aeroplanes to oil pipelines stay safe and sound. Isn’t PAUT kind of amazing?

Advantages of PAUT

PAUT makes checking for tricky bits in materials a breeze, and it’s quick too. It helps catch more flaws faster, giving folks peace of mind about their gear.

Simplified inspection and interpretation

Simplified inspection and interpretation make PAUT stand out. It’s like having a super smart tool that quickly tells you if something’s wrong with critical assets, such as pipes or bolts.

With PAUT, reading the results is easier because it shows clear pictures of what’s inside an object. This means less guessing and more knowing for sure if there’s a problem.

This easy-to-understand approach helps people who do inspections work faster and smarter. They can spot flaws quicker than with old-school methods. Plus, because the images are so clear, there’s less room for error.

This makes everyone happier – from the folks doing the inspecting to those waiting on the results to ensure everything is safe and sound.

Increased flaw detection

PAUT stands out for its knack in finding more flaws than other NDT techniques. It’s like having a superpower to see things you couldn’t before. With PAUT, inspections cover wider areas and spot problems fast.

This means ships, pipes, and even aerospace parts get a thorough check-up ensuring nothing nasty is hiding.

This tech digs deep into material surfaces, catching cracks and voids early on. A real game-changer in keeping critical assets safe! Now, zooming past flaw detection brings us face-to-face with another cool perk – the speed of these inspections.

Faster inspection speeds

So, after spotting more flaws with PAUT, things get even better because this tech speeds up the whole inspection process. Imagine scanning a huge pipe or a ship’s hull and finishing up way quicker than you thought possible.

That’s what we’re talking about here. This speed isn’t just good for saving time; it means less downtime for equipment or structures being checked out. They can be back in action faster, keeping things running smoothly.

This quickness comes from how PAUT sends out several ultrasound beams at once. Instead of going over the same spot many times, it covers larger areas in one go. Think of it like painting a wall with a massive brush instead of a tiny one – you’ll finish much quicker, right? This method makes sure nothing gets missed while also getting the job done in record time.

More reliable results

PAUT helps find flaws and defects in important things like ships and pipes. This method is better at finding problems than older ways. With PAUT, you get results you can trust more.

People who use PAUT can be sure they are getting a clear picture of any issues. This means safer boats, pipes, and other stuff we use every day.

Trust in the results matters a lot. That’s why many industries prefer PAUT for checking their gear. From planes to cars, knowing that something has been checked properly gives peace of mind.

Plus, using PAUT means fewer mistakes and less guesswork about where problems might be. In short, it makes everything a bit safer and more reliable for everyone involved.

Disadvantages of PAUT

PAUT sounds great, but it’s not perfect. There are a few hiccups, like some jobs it just can’t handle and the fact that it can get pretty complex and pricey.

Applicability limitations

Not all materials can say “hello” to Phased Array Ultrasonic Testing (PAUT). Some are like uninvited guests at a party, not fitting in. Why? Well, certain materials absorb sound waves more than others or have complex shapes that make it tricky.

PAUT also has trouble inspecting really thin or really thick items. Like trying to listen through a super thick wall – sometimes you just can’t hear what’s on the other side.

Now here’s the kicker: while PAUT is brilliant for finding flaws in ships, tubes, and bolts among other things, it doesn’t work well with every kind of material out there. Picture trying to use your mobile phone where there’s no signal – a bit frustrating, right? That’s kinda how it goes with PAUT in some situations.

Moving onto another thought..

Complexity

PAUT, or Phased Array Ultrasonic Testing, isn’t just a walk in the park. This technique uses advanced tech to check for flaws in materials without breaking them. Yet, making sense of it all is tough.

You need proper training to understand how to use the equipment and interpret the results accurately. It’s like trying to read a map in another language; if you don’t know what you’re looking at, you could end up lost.

So, while PAUT offers top-notch inspection services and gets used across major industries like aerospace and manufacturing, mastering it takes effort. The equipment itself has many parts – think of transducers that send out sound waves and detectors that catch them.

Plus, you’ve got to be pretty sharp with computers since PAUT relies heavily on software for data analysis. It’s not something anyone can pick up overnight; learning to get it right needs time and patience.

Cost

Phased Array Ultrasonic Testing (PAUT) isn’t cheap—there’s no way around it. The tech and gear needed for this kind of nondestructive testing (NDT) are top-notch. You need a bunch of advanced equipment like ultrasonic sensors and phased array transducers.

These items help find flaws in materials but, yep, they do bump up the price.

The bright side? Investing in PAUT can save money over time. By catching defects early, you avoid bigger headaches later on with critical assets needing expensive fixes or replacements.

Think of it as paying upfront to dodge higher costs down the line—not a bad trade-off if you ask me.

Applications of PAUT

PAUT does a top job in finding problems that we can’t see with our eyes. It’s like having superpowers for checking things like planes, cars, and big machines to make sure they are safe and sound.

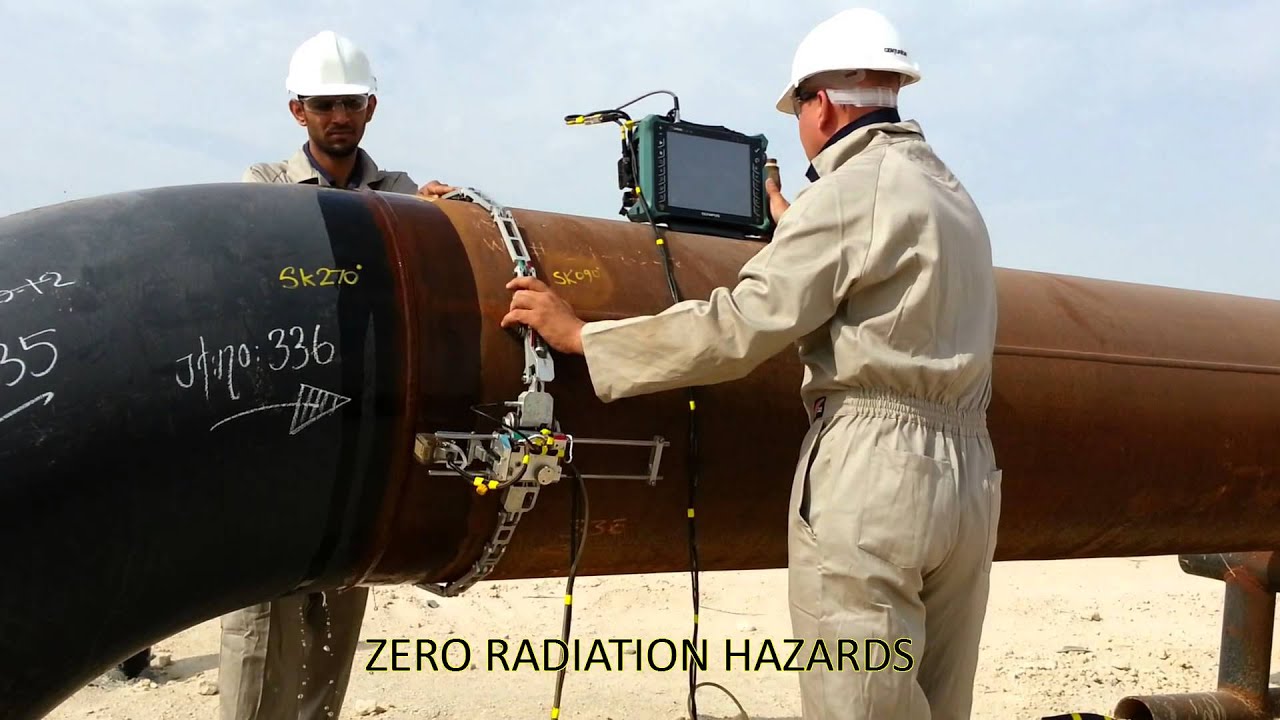

Inspection of process equipment

Inspecting process equipment is a crucial step in making sure everything runs smoothly and safely. With PAUT, or Phased Array Ultrasonic Testing, we get to spot flaws like cracks, corrosion, or other defects in critical assets such as pipes, tubes, and bolts.

This advanced method shines because it sees problems that might cause big troubles later on. Plus, it works quickly and gives very reliable results.

Using this technology means inspections are less of a headache and more of a breeze. It lets inspectors check out hard-to-reach areas without having to take apart the machinery. This way, businesses can keep their gear running without too much downtime.

So yeah, PAUT plays a big part in keeping things safe and saving time and money for industries far and wide.

Detecting cracks, voids, and pits

Moving from inspecting big equipment, PAUT is a champ at finding small troubles too. Cracks, voids, and pits? No worries. This tech shines a light on them all before they turn into big headaches.

It sends out sound waves that bounce back when they hit something not quite right, giving the experts a heads-up to fix things up quick smart.

Using this method means nothing gets missed. It’s like having super-vision for metal! Whether it’s in pipes, bolts or even the wings of an airplane, PAUT spots the tiniest flaws. This keeps everything running smoothly and safely without taking things apart or causing any damage.

It’s pretty clever stuff.

Aerospace and automotive industry

After spotting cracks, voids, and pits with PAUT, we find ourselves zooming into where this tech shines bright – the aerospace and automotive industry. Planes flying high and cars zooming by rely on parts that are top-notch.

No room for errors here! That’s where Phased Array Ultrasonic Testing steps in like a superhero. It checks planes and car parts with eyes sharper than an eagle’s. This means finding tiny flaws before they turn into big problems.

In these industries, speed is key but safety? Well, that’s everything. With PAUT in their toolkit, folks can inspect large areas fast without missing a beat. Plus, because it’s so good at catching issues early on, making repairs is cheaper and easier.

It keeps planes soaring safely in the sky and cars cruising smoothly on roads. Really now, thanks to PAUT’s knack for detail and efficiency – everyone sleeps better at night knowing travel is safer all around.

Phased Array Ultrasound Transducer

A Phased Array Ultrasound Transducer is like your mate who can listen to metal and tell you if something’s off inside – pretty cool, eh? Keen to find out more about these clever tools? Keep reading!

Definition and function

Phased Array Ultrasonic Testing, or PAUT, is a smart method used for checking if things like tubes, pipes, and ships have any sneaky cracks or defects without breaking them apart. Think of it as being a bit like a super-detailed X-ray that can spot tiny problems inside important stuff before they turn into big issues.

This technique uses special tools called ultrasonic transducers to send sound waves into the materials being checked. These sound waves bounce back when they hit something strange inside the material, telling us where and what the problem might be.

The heart of PAUT lies in its ability to use multiple angles and elements within a single probe head. This means it’s not just sending one wave straight down; it’s more like casting a net of sound waves from different directions all at once.

This cool trick lets inspectors see flaws in 3D and figure out their size, shape, and danger level way better than older methods could. Plus – bonus points – it gives clearer pictures faster which makes everyone’s job easier!

Types of transducers used in PAUT

PAUT, short for Phased Array Ultrasonic Testing, uses special gear called transducers. These transducers send out sound waves to check materials for faults. They’re a big deal in industries where safety and quality matter a lot. Here’s a look at the different types you might come across:

- Linear Array Transducers: These are your go-to for scanning big, flat areas. Think of them like a flashlight that sweeps across a surface to spot any hidden issues.

- Annular Array Transducers: Picture these as superheroes for checking out round objects, like pipes or tubes. They wrap around the curve perfectly, making sure nothing dodgy slips through.

- Matrix Array Transducers: Now, these are the fancy ones. They can look in multiple directions at once! Ideal for complicated shapes where you need eyes everywhere.

- Sectorial Array Transducers: Grab one of these when you need to peek around corners or into tight spots. They’re great at angling their sound beams to uncover secrets hidden from straight-on views.

Each type has its own superpower, helping inspectors find even the sneakiest of defects in everything from aeroplanes to pipelines. Gotta love how this tech makes sure things stay safe and sound!

Conclusion

PAUT works by sending sound waves into materials. Think of it like shouting into a canyon and waiting for the echo. But instead of your shout, it uses special sound waves that bounce back to tell us if there are any hidden problems.

This cool tool has a few pieces: the machine that makes the sound waves, something to hold it against what we’re checking, and a screen that shows what the sounds find inside.

Now for the good stuff—why people love using PAUT:

– It’s easy to use once you get the hang of it.

– Finds tiny flaws really well.

– Works fast so you can check lots of things quickly.

– Gives trusted results which helps avoid big problems down the track.

But nothing’s perfect, right? Here are some not

Overview of PAUT

PAUT stands for Phased Array Ultrasonic Testing, and it’s a smart way to check out stuff without breaking it. Imagine using sound waves that are so high-pitched, humans can’t hear them.

These sound waves travel through materials like metals and composites used in all sorts of industries – from airplanes to bridges. The cool bit? By adjusting the sound waves’ angles and focusing them on specific spots, PAUT can see inside these materials.

It spots cracks, voids, or anything else that shouldn’t be there.

This method uses a bunch of tiny sensors lined up in a row (that’s the “phased array” part). These little guys work together to steer beams of ultrasonic energy into the material being checked.

They can sweep over an area much faster than traditional testing methods. And because they collect heaps of data about what’s inside, engineers can make really informed decisions about whether something is safe or needs fixing.

Plus, with computers getting smarter every day, interpreting this data has become quicker and more accurate than ever before! So yeah, PAUT helps keep our critical assets safe by finding tiny problems before they turn into big ones.

Growing use and popularity

Lots of industries are now saying “yes” to using PAUT for checking their big and important machines. Why? Because this method finds tiny problems that other checks might miss, making it a top pick for keeping things like ships, pipes, and cars safe.

With its smart way of looking into materials without breaking them apart, PAUT has become a go-to for folks in aerospace, manufacturing, and defense. They love how it gives clear pictures of what’s inside something fast.

This trend isn’t slowing down either. More companies are getting on board with PAUT because they see how well it works for spotting flaws in all sorts of materials. This means we’re likely to hear more about PAUT as more sectors start to rely on its precision and reliability to protect their gear.

From flying high in the sky to deep-sea adventures, PAUT is proving its worth every day by helping keep critical stuff in tip-top shape.

Resources and References

For anyone keen to dive deeper into Phased Array Ultrasonic Testing (PAUT) in NDT Inspection, a wealth of resources await. Books, academic papers, online courses and forums shed light on the finer details.

Industry experts often share insights through webinars and workshops. Don’t forget about companies that offer PAUT services—they frequently publish case studies and technical guides which can be goldmines of practical information.

Exploring these materials brings the world of PAUT closer, making it easier to grasp how this technology shapes industries from aerospace to manufacturing. Whether you’re a student starting out or a professional honing your skills, tapping into these references will arm you with knowledge and perhaps spark new ideas for innovation in nondestructive testing techniques.

NDT Level 3 Services

Our team of highly skilled freelance Phased Array Ultrasonic Testing (PAUT) Level 3 professionals is equipped to address all of your inspection requirements, ensuring that minor defects are identified and resolved before they escalate into significant issues that could disrupt production and lead to other operational complications. With an in-depth understanding of PAUT technology and its applications across various industries, our experts are adept at developing comprehensive PAUT methodologies, drafting detailed procedures, performing validations, and conducting thorough data analysis, among a plethora of other specialized services.

We pride ourselves on our ability to deliver bespoke solutions tailored to the unique needs of each client, focusing on maximizing the integrity and reliability of your assets. Our team is committed to implementing best practices and leveraging the latest advancements in PAUT technology to enhance the safety, efficiency, and cost-effectiveness of your operations. Whether you require assistance in establishing inspection criteria, optimizing inspection workflows, or interpreting complex PAUT data for critical decision-making, our professionals are here to provide unparalleled support and expertise.

By partnering with us, you gain access to a wealth of knowledge and experience in non-destructive testing (NDT), allowing you to make informed decisions and maintain the highest standards of quality and safety in your projects and facilities. Let our freelance PAUT Level 3 professionals assist you in navigating the complexities of PAUT inspection and ensure that your assets remain in optimal condition, free from defects that could potentially compromise their performance and your business’s continuity.